1. Nānā Haʻawina Mea

ʻO ka paipu kila kila 347H he kila kila austenitic i hoʻopaʻa ʻia me ka niobium kiʻekiʻe-kalapona i ʻike ʻia no kona ikaika wela kiʻekiʻe, ka hiki ke hoʻopili maikaʻi ʻia, a me ke kūpaʻa koʻikoʻi i ka corrosion intergranular. Hoʻomaikaʻi ka hoʻohui ʻana o ka niobium (Nb) i ka ikaika kolo a pale i ka hoʻokahe ʻana o ka chromium carbide ma nā palena o ka palaoa, e hōʻoiaʻiʻo ana i ka pale ʻana i ka sensitization.

2.Ka Hoʻohui Kemika (Maʻamau)

| ʻElemene | ʻIke (%) |

| C | 0.04 – 0.10 |

| Cr | 17.0 – 19.0 |

| Ni | 9.0 – 13.0 |

| Si | ≤1.0 |

| Mn | ≤ 2.00 |

| P | ≤ 0.045 |

| S | ≤ 0.030 |

3. Nā Waiwai Mekanika a me ka ʻAʻai ʻana

Nā Waiwai Mekanika (ASTM A213):

- Ikaika Tensile ≥ 515 MPa

- Ikaika Hāʻawi ≥ 205 MPa

- Elongation ≥ 35%

- Ka ikaika haki kolo ma 600°C: >100 MPa

Ke kū'ē ʻana i ka palaho:

- Ke kūpaʻa maikaʻi loa i ka pala intergranular ma muli o ka hoʻopaʻa ʻana o Nb

- Ke kūpaʻa maikaʻi i ka waikawa nitric, ka waikawa acetic, nā wahi alkaline, a me ka wai kai

- Hoʻāʻo ʻia no ka pala o ka paʻakai heheʻe, hana i hōʻoia ʻia i loko o nā pahu mālama paʻakai heheʻe CSP

- ʻOi aku ka maʻalahi o ka pitting i hoʻoulu ʻia e ka chloride ma mua o 316L, i hoʻēmi ʻia e ka passivation a me ka mālama ʻana i ka ʻili

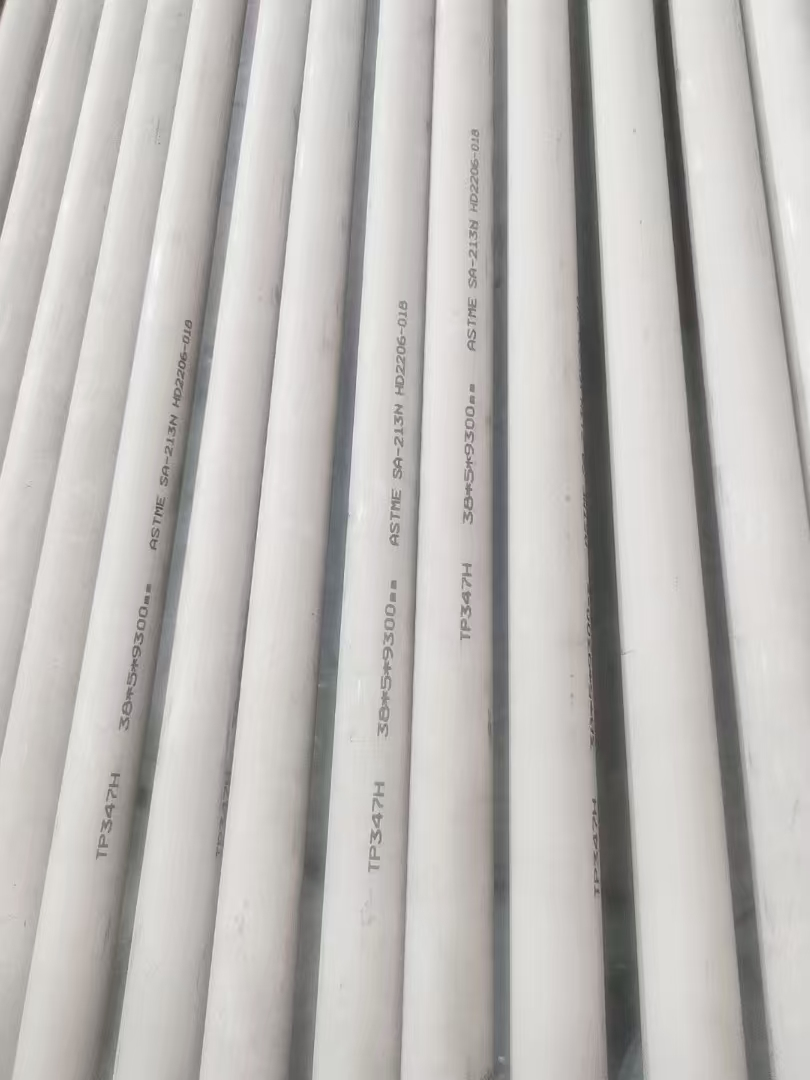

4. Nā kikoʻī huahana maʻamau

Nā Ana:

- Paipu ʻAʻohe ʻŌnaehana: OD 1/4”–36”, mānoanoa o ka paia SCH10–SCH160

- Nā Paipu Kikoʻī: OD 10mm–108mm, huki anu ʻia

- Paipu Welded: Nā paipu paia lahilahi a mānoanoa me ka hoʻohana ʻana i ka TIG, PAW, a me ka SAW welding

- Loa: A hiki i 12 mika; loaʻa nā lōʻihi ʻoki maʻamau

Nā Kūlana Hana Hana:

- ASTM A213/A312, ASME SA213/SA312

- EN 10216-5, GB/T 5310

- Kūlike me ke kūlana o ka ipu kaomi: PED, AD2000 W0, ASME Code Section VIII Div. 1

5. Kaʻina Hana Hana

1. Mea Maka: Nā bila kila i hōʻoia ʻia mai nā wili kūloko a me ke ao holoʻokoʻa

2. ʻŌwili Wela: Nā bila i hoʻomehana ʻia i 1150–1200°C, i hou ʻia a ʻōwili ʻia no nā paipu nui a i ʻole nā paipu paia mānoanoa

3. Kaha Kiʻi Anu: Kaha kiʻi anu he nui no ka nui pololei a me ka hoʻopau ʻana o ka ʻili

4. Ka Lapaʻau Wela: Hoʻoheheʻe ʻia ka hopena ma 980–1150°C, hoʻopau wikiwiki i ka wai e kāohi i ka ua carbide

5. Kuʻihao: Nā kaʻina hana GTAW (TIG), PAW, a me SAW, me ka hoʻohana ʻana i ka uea hoʻopihapiha ER347 no ka hoʻopaʻa ʻana; loaʻa nā koho hoʻomaʻemaʻe hope

6. Hoʻopau ʻili: Pickling, passivation (HNO₃/HF), a me ka polishing mechanical (Ra ≤ 0.2µm ma ke noi)

7. Nānā: 100% RT (hoʻāʻo radiographic) no nā wili; ultrasonic, hydrostatic, PMI, hoʻāʻo ʻana i ka corrosion intergranular e like me ka mea e pono ai

6. Palapala Hōʻoia a me ka Mana Kūlana

Ua hōʻoia ʻia nā paipu kila kila 347H o Womic Steel ma lalo o:

- ISO 9001:2015

- PED 2014/68/EU

- AD2000 W0

- ASME Boiler & Pressure Vessel Code

Hoʻomaʻamaʻa koʻikoʻi kēlā me kēia pūʻulu, me:

- Nā hoʻāʻo mīkini (tensile, impact, flattening, flaring)

- Nā hoʻāʻo ʻana i ka palaho (IGC no ASTM A262)

- Hoʻāʻo ʻole luku (UT, RT, Eddy current)

- Nānā ʻana i nā ana a me ka hiki ke loaʻa piha

7. Nā Kahua Noi

Hoʻohana nui ʻia ka paipu kila kila 347H i loko o:

- Hana Mana: Nā mea hoʻomehana nui, nā mea hoʻomehana hou, nā paipu mahu nui i nā mea kanu mana wela subcritical a me supercritical

- Ikehu Wela o ka Lā: Nā pahu mālama wela paʻakai i hoʻoheheʻe ʻia (450–565°C), ua hōʻoia ʻia ka hoʻohana ʻana ma nā papahana ma Kina (Yumen, Haixi)

- Petrochemical: Nā ʻōmole umu, nā mea hana hydroprocessing (kū i nā wahi H₂-H₂S-H₂O)

- Aerospace: Nā ʻauwai hoʻopau mīkini a me nā paipu hoʻolako ea turbine (hana a hiki i 850°C)

- Nā Mea Hoʻololi Wela: Nā mea hoʻohuihui wela kiʻekiʻe a me nā paipu i loko o nā hale hoʻomaʻemaʻe a me nā ʻōnaehana moana

8. Ka Manawa Alakaʻi Hana

- Nā Paipu Seamless (Nā Nui Maʻamau): 15–25 mau lā

- Nā Ana Kūikawā/Paipa Mānoanoa: 30–45 mau lā

- Nā Kauoha Nui: ʻO ka hiki ke lawe ʻia ma luna o 3,000 tons/mahina e hōʻoiaʻiʻo ana i ka lawe wikiwiki ʻana ma lalo o nā manawa wikiwiki

9. Hoʻopili a me ka Logistics

Hāʻawi ʻo Womic Steel i ka hoʻopili palekana a hiki ke hoʻopilikino ʻia:

- Nā Hihia Lāʻau Seaworthy a i ʻole nā Pūʻolo Kila

- Nā pāpale hopena palaki, ka ʻaila anti-rust, a me ka ʻōwili ʻiliʻili

- Ua kūlike nā ʻōpala hoʻokuʻu aku a pau me nā kūlana ISPM-15

Ka Pōmaikaʻi Logistics:

- Nā kumukūʻai CIF/CFR hoʻokūkū

- Hoʻouna wikiwiki ʻia mai ke awa a i ka puka i Asia Hikina Hema, India, ʻEulopa, a me ka Hikina Waena

- Hoʻoikaika ʻia ka ukana no ka pale ʻana i ke kūlou ʻana, ka pale ʻana i ka paheʻe ʻana, a me ke kūʻē ʻana i ke kuʻi ʻana i ka wā o ka hoʻouna ʻana

10. Nā lawelawe hana

- Ke kūlou ʻana (anu a me ke ʻano wela)

- ʻOki pololei

- Ke kaula ʻana a me ka hoʻopau ʻana i ka hoʻopau ʻana

- ʻAha hoʻoheheʻe (nā spools a me nā kuʻekuʻe lima)

- Machining maʻamau no kēlā me kēia kiʻi

11. No ke aha e koho ai iā Womic Steel?

- Keʻena Hoʻokolohua a me ka Hoʻomohala (R&D) ma loko o ka hale

- ʻO ke kaulahao lako paʻa o nā mea maka e hōʻoiaʻiʻo i nā pōʻaiapuni hoʻouna pōkole

- He mau makahiki o ka ʻike metallurgical, ʻoi aku hoʻi i nā metala wela kiʻekiʻe

- Ka hiki ke hahai piha ʻia a me nā palapala no ka mālama ʻana i nā lako hana kaomi

- Mea hoʻolako hoʻonā hoʻokahi no ke kūʻai ʻana, ka hana ʻana, a me ka hoʻokuʻu aku i nā ʻōnaehana paipu kila kila

No nā pepa ʻikepili loea, nā kumukūʻai, a me nā ʻōlelo hoʻopuka papahana maʻamau, e kelepona iā Womic Steel i kēia lā. Ua mākaukau mākou e kākoʻo i kāu mau pono paipu hana kiʻekiʻe me ka pololei, ka wikiwiki, a me ka pono.

E koho iā Womic Steel Group ma ke ʻano he hoa hilinaʻi nouNā paipu kila kilaa me ka hana hoʻouna lanakila ʻole. Welina mai i ka nīnau!

Pūnaewele: www.womicsteel.com

Leka uila: sales@womicsteel.com

Kelepona/WhatsApp/WeChat: Victor: +86-15575100681 a i ʻole Jack: +86-18390957568

Ka manawa hoʻouna: ʻApelila-16-2025