ʻO ke kila kila kila ka pōkole o ke kila kila kūpaʻa waikawa, ea, mahu, wai a me nā mea ʻino ʻē aʻe nāwaliwali a i ʻole ke kila kila i kapa ʻia he kila kila; a e kūpaʻa i nā mea ʻino kemika (nā waikawa, alkalis, paʻakai, a me nā impregnation kemika ʻē aʻe) ʻo ka pala o ke kila i kapa ʻia he kila kūpaʻa waikawa.

ʻO ke kila kila ʻole e pili ana i ka ea, ka mahu, ka wai a me nā mea ʻino ʻē aʻe a me nā waikawa, alkalis, paʻakai a me nā mea ʻino kemika ʻē aʻe o ke kila, i ʻike ʻia hoʻi he kila kūpaʻa waikawa kila. I ka hana maoli, pinepine nā mea ʻino palupalu i kapa ʻia he kila kila, a me nā mea kemika kila i kapa ʻia he kila kūpaʻa waikawa. Ma muli o nā ʻokoʻa o ke ʻano kemika o nā mea ʻelua, ʻaʻole pono ka mea mua e kū i ka palaho o nā mea kemika, a ʻo ka mea hope he kila kila. ʻO ke kūpaʻa o ke kila kila e pili ana i nā mea hoʻohuihui i loko o ke kila.

Ka Hoʻokaʻawale Maʻamau

Wahi a ka hui metallurgical

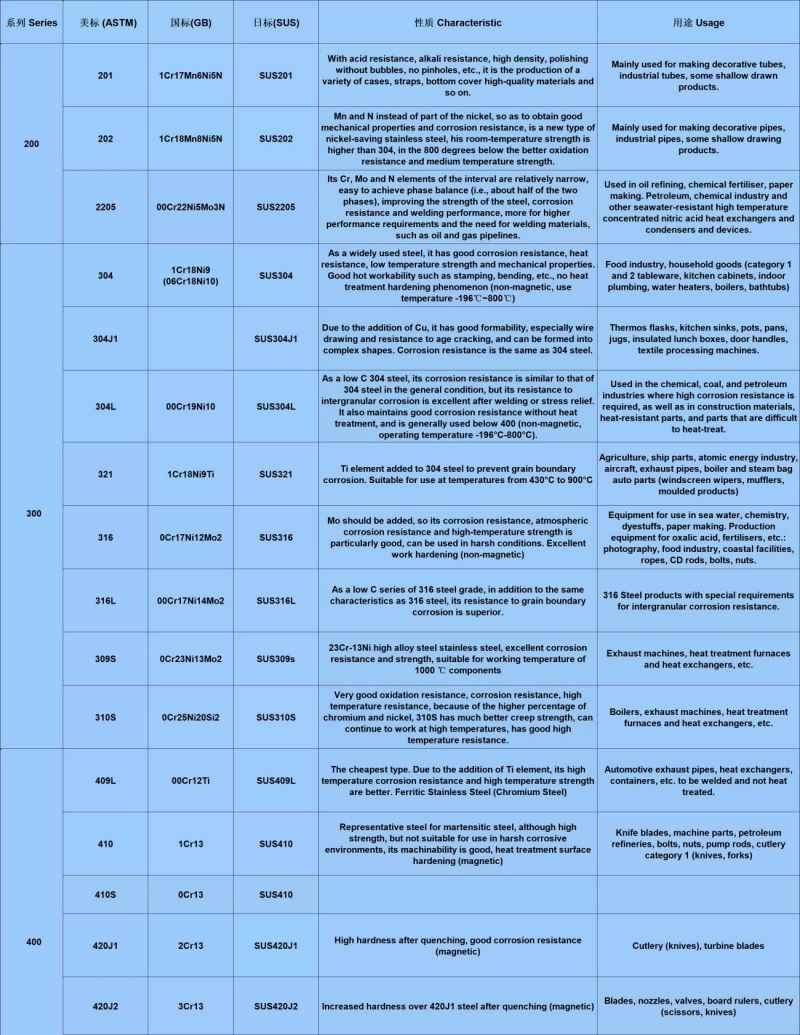

Ma keʻano laulā, e like me ka hui metallurgical, ua māhele ʻia nā kila kila maʻamau i ʻekolu mau māhele: nā kila kila austenitic, nā kila kila ferritic a me nā kila kila martensitic. Ma ke kumu o ka hoʻonohonoho metallurgical kumu o kēia mau māhele ʻekolu, ua loaʻa nā kila duplex, nā kila kila paʻakikī precipitation a me nā kila alloy kiʻekiʻe e loaʻa ana ka hao ma lalo o 50% no nā pono a me nā kumu kikoʻī.

1. Ke kila kila Austenitic

ʻO ka matrix i ke ʻano kristal cubic i waenakonu o ka hui austenitic (CY phase) i hoʻomalu ʻia e ka non-magnetic, ʻo ia hoʻi ma o ka hana anu e hoʻoikaika ai (a hiki ke alakaʻi i kahi kekelē o ka magnetism) o ke kila kila. ʻO ka American Iron and Steel Institute i 200 a me 300 moʻo o nā lepili helu, e like me 304.

2. Ke kila kila Ferritic

ʻO ke ʻano o ka hui ferrite (kahi pae) he matrix i kikowaena ʻia i ke kino, he magnetic, ʻaʻole hiki ke hoʻopaʻakikī ʻia e ka mālama wela, akā hiki i ka hana anu ke hoʻoikaika iki i ke kila kila. ʻO ka American Iron and Steel Institute i 430 a me 446 no ka lepili.

3. Ke kila kila Martensitic

ʻO ka matrix he hui martensitic (cubic a cubic paha i waenakonu o ke kino), magnetic, ma o ka mālama wela hiki ke hoʻoponopono i kona mau waiwai mechanical o ke kila kila. ʻO ka American Iron and Steel Institute i 410, 420, a me 440 mau helu i hōʻailona ʻia. Loaʻa iā Martensite kahi hui austenitic i nā mahana kiʻekiʻe, hiki ke hoʻololi ʻia i martensite (ʻo ia hoʻi ka paʻakikī) ke hoʻomaʻalili ʻia i ka mahana o ka lumi ma kahi wikiwiki kūpono.

4. Austenitic he ferrite (duplex) ʻano kila kila

Loaʻa i ka matrix nā hoʻonohonoho ʻelua-phase austenitic a me ferrite, ʻo ia hoʻi ka nui o ka matrix phase liʻiliʻi ma mua o 15%, magnetic, hiki ke hoʻoikaika ʻia e ka hana anu o ke kila kila, 329 kahi kila kila duplex maʻamau. Hoʻohālikelike ʻia me ke kila kila austenitic, ua hoʻomaikaʻi nui ʻia ke kila duplex, ke kūʻē ʻana i ka intergranular corrosion a me ka chloride stress corrosion a me ka pitting corrosion.

5. Ke kila kila paʻakikī

He hui austenitic a martensitic paha ka matrix, a hiki ke hoʻopaʻakikī ʻia e ka mālama ʻana i ka hoʻopaʻakikī ʻana i ka wai e hoʻopaʻakikī ai i ke kila kila. ʻO ka American Iron and Steel Institute i 600 mau moʻo o nā lepili kikohoʻe, e like me 630, ʻo ia hoʻi, 17-4PH.

Ma keʻano laulā, me ka hoʻohui ʻana i nā mea hao, ʻoi aku ka maikaʻi o ke kūpaʻa ʻana o ke kila kila austenitic i ka corrosion, i loko o kahi ʻano corrosive ʻole, hiki iā ʻoe ke hoʻohana i ke kila kila ferritic, i loko o nā ʻano corrosive iki, inā pono ka mea e loaʻa ai ka ikaika kiʻekiʻe a i ʻole ka paʻakikī kiʻekiʻe, hiki iā ʻoe ke hoʻohana i ke kila kila martensitic a me ka hoʻokē ʻana i ke kila kila.

Nā ʻano a me nā hoʻohana

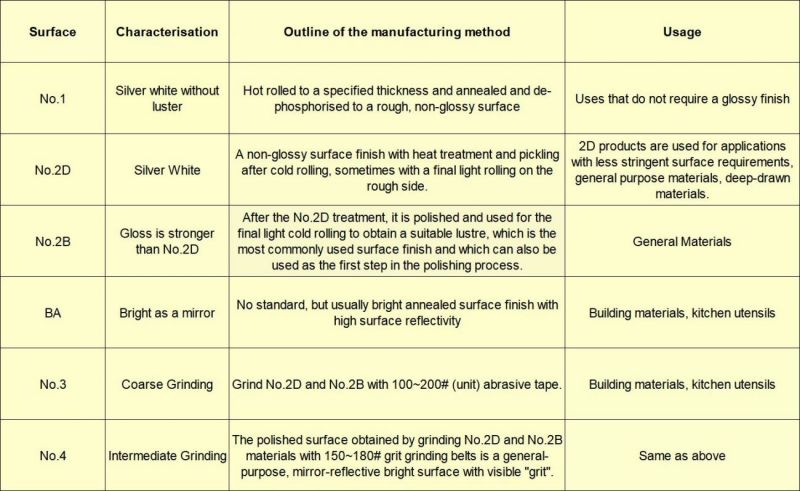

Kaʻina hana ʻili

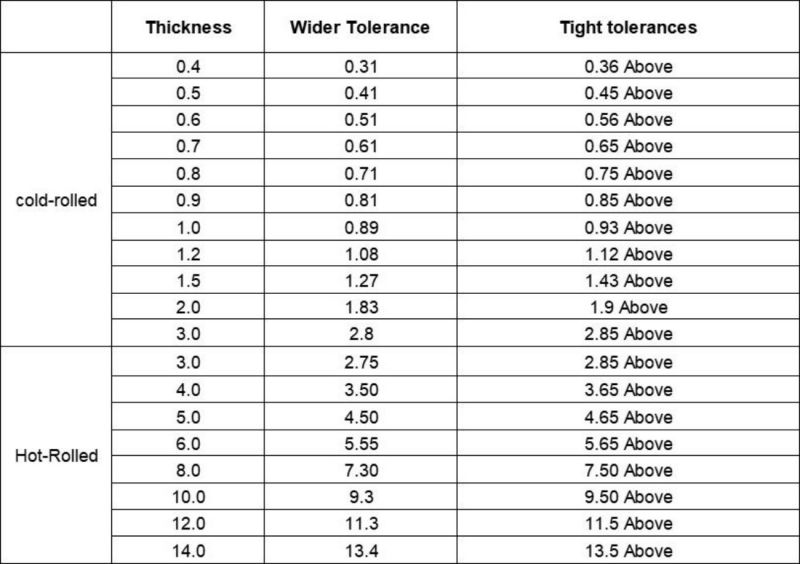

ʻOkoʻa ka mānoanoa

1. Ma muli o ke kaʻina hana ʻōwili o ka mīkini wili kila, ua hoʻomehana ʻia nā ʻōwili e kahi deformation iki, e hopena ana i ka ʻōwili ʻana i ka ʻokoʻa o ka mānoanoa o ka papa, ʻo ka mānoanoa ma waena o nā ʻaoʻao ʻelua o ka lahilahi. I ke ana ʻana i ka mānoanoa o ka papa, pono e ana ʻia nā lula mokuʻāina ma waenakonu o ke poʻo papa.

2. ʻO ke kumu o ke ahonui ma muli o ke koi a ka mākeke a me ka mea kūʻai aku, i māhele ʻia i nā ʻae nui a me nā ʻae liʻiliʻi.

V. Nā koi hana, nānā ʻana

1. Pā paipu

① nā hui ʻokiʻoki i hoʻopili ʻia no ka nānā ʻana i ka hihi 100% a i ʻole UT, pae kūpono: RT: Ⅱ UT: pae Ⅰ;

② Ma waho aʻe o ke kila kila, hoʻopili ʻia ka pā paipu spliced stress relief wela treatment;

③ ka ʻokoʻa ākea o ke alahaka o ka lua o ka papa paipu: e like me ke ʻano no ka helu ʻana i ka laulā o ke alahaka o ka lua: B = (S - d) - D1

Ka laulā haʻahaʻa loa o ke alahaka lua: B = 1/2 (S - d) + C;

2. Ka mālama wela ʻana o ka pahu Tube:

ʻO ke kila kalapona, ke kila metala haʻahaʻa i hoʻopaʻa ʻia me ka ʻāpana māhelehele o ka pahu paipu, a me ka pahu paipu o nā puka ʻaoʻao ma mua o 1/3 o ke anawaena o loko o ka pahu paipu cylinder, i ka hoʻopili ʻana o ka hoʻopaʻa ʻana no ka hoʻomaha ʻana i ke kaumaha, pono e hana ʻia ka ʻili sila flange a me ka ʻāpana ma hope o ka mālama wela.

3. Hoʻāʻo kaomi

Ke haʻahaʻa ke kaomi hoʻolālā hana pūpū ma mua o ke kaomi hana paipu, i mea e nānā ai i ka maikaʻi o ka paipu hoʻololi wela a me nā pilina pā paipu

① Hoʻonui ke kaomi papahana pūpū i ke kaomi hoʻāʻo me ka papahana paipu e kūlike me ka hoʻāʻo hydraulic, e nānā inā he leakage o nā hui paipu. (Eia nō naʻe, pono e hōʻoia i ke koʻikoʻi kiʻiʻoniʻoni mua o ka pūpū i ka wā o ka hoʻāʻo hydraulic he ≤0.9ReLΦ)

② Ke kūpono ʻole ke ʻano hana ma luna, hiki ke hoʻāʻo hydrostatic ka pūpū e like me ke kaomi mua ma hope o ka hala ʻana, a laila ka pūpū no ka hoʻāʻo liki ammonia a i ʻole ka hoʻāʻo liki halogen.

He aha ke ʻano kila kila ʻaʻole maʻalahi ke popo?

ʻEkolu mau kumu nui e hoʻopilikia ai i ka popo ʻana o ke kila kila:

1. ʻO ka nui o nā mea hoʻohuihui. Ma keʻano laulā, ʻaʻole maʻalahi ka popo o ka chromium i loko o ke kila 10.5%. ʻOi aku ka maikaʻi o ke kūpaʻa ʻana o ka chromium a me ka nickel i ka pala, e like me ka 304 nickel o 85 ~ 10%, a me 18% ~ 20% ka nui o ka chromium, ʻaʻole ia he popo ma ke ʻano laulā.

2. E hoʻopilikia pū ke kaʻina hana hoʻoheheʻe ʻana o ka mea hana i ke kūpaʻa ʻana o ke kila kila kila. He maikaʻi ka ʻenehana hoʻoheheʻe ʻana, nā lako holomua, nā ʻenehana holomua, nā hale hana kila kila kila nui i ka kaohi ʻana i nā mea hoʻohuihui, ka wehe ʻana i nā haumia, hiki ke hōʻoia ʻia ka kaohi ʻana i ka mahana hoʻoluʻu billet, no laila he paʻa a hilinaʻi hoʻi ka maikaʻi o ka huahana, maikaʻi ke ʻano kūloko, ʻaʻole maʻalahi ka popo. Ma ke ʻano ʻē aʻe, kekahi mau lako hale hana kila kila liʻiliʻi i hope, ʻenehana hope, ka hana hoʻoheheʻe ʻana, ʻaʻole hiki ke wehe ʻia nā haumia, e popo mau ka hana ʻana o nā huahana.

3. Kaiapuni waho. ʻAʻole maʻalahi ka popo i kahi maloʻo a me ka ea, ʻoiai ʻo ka makū o ka ea, ke ua mau, a i ʻole ka ea e loaʻa ana ka acidity a me ka alkalinity o ke kaiapuni e maʻalahi ke popo. ʻO ke kila kila kila 304, inā ʻilihune loa ke kaiapuni a puni, he popo nō hoʻi.

Pehea e hana ai me nā kiko popo kila kila?

1. Ke ʻano hana kemika

Me ka hoʻopili pickling a i ʻole ka pīpī e kōkua i kona mau ʻāpana i popo ʻia e hoʻihoʻi i ka hoʻokumu ʻia ʻana o ka ʻili chromium oxide e hoʻihoʻi i kona kūpaʻa i ka pala, ma hope o ka pickling, i mea e wehe ai i nā mea haumia a me nā koena waikawa, he mea nui loa ia e holoi pono me ka wai. Ma hope o ka hana ʻia ʻana o nā mea āpau a hoʻopili hou ʻia me nā lako polishing, hiki ke pani ʻia me ka wax polishing. No nā wahi popo liʻiliʻi kūloko hiki ke hoʻohana ʻia 1:1 petrol, hui ʻaila me kahi lole maʻemaʻe e holoi i nā wahi popo.

2. Nā ʻano hana mīkini

ʻO ka hoʻomaʻemaʻe ʻana i ke one, ka hoʻomaʻemaʻe ʻana me ke aniani a i ʻole nā mea keramika e pahū ana, ka luku ʻana, ka palaki ʻana a me ka poli ʻana. Loaʻa i nā ʻano hana mīkini ka hiki ke holoi i ka haumia i hoʻokumu ʻia e nā mea i lawe mua ʻia, nā mea poli a i ʻole nā mea i luku ʻia. ʻO nā ʻano haumia āpau, ʻoiai nā ʻāpana hao haole, hiki ke lilo i kumu o ka pala, ʻoi aku hoʻi i nā wahi pulu. No laila, ʻoi aku ka maikaʻi o ka hoʻomaʻemaʻe ʻia ʻana o nā ʻili i hoʻomaʻemaʻe ʻia me ka mīkini ma lalo o nā kūlana maloʻo. ʻO ka hoʻohana ʻana i nā ʻano hana mīkini e hoʻomaʻemaʻe wale i kona ʻili a ʻaʻole e hoʻololi i ke kūpaʻa ʻana o ka mea ponoʻī. No laila, ua ʻōlelo ʻia e poli hou i ka ʻili me nā lako poli a pani iā ia me ka wax poli ma hope o ka hoʻomaʻemaʻe ʻana me ka mīkini.

Nā ʻano a me nā waiwai o ke kila kila i hoʻohana pinepine ʻia

1.304 kila kila. ʻO ia kekahi o nā kila kila austenitic me ka noi nui a me ka hoʻohana ākea loa, kūpono no ka hana ʻana i nā ʻāpana hoʻoheheʻe hohonu a me nā paipu waikawa, nā ipu, nā ʻāpana kūkulu, nā ʻano kino mea hana like ʻole, a pēlā aku. Hiki iā ia ke hana i nā lako a me nā ʻāpana non-magnetic, haʻahaʻa-mahana.

2.304L kila kila. I mea e hoʻoponopono ai i ka ua ʻana o Cr23C6 i hoʻokumu ʻia e ke kila kila 304 ma kekahi mau kūlana aia kahi ʻano koʻikoʻi i ka corrosion intergranular a me ka hoʻomohala ʻana o ke kila kila austenitic kalapona ultra-low, ʻoi aku ka maikaʻi o kona kūlana sensitized o ke kūpaʻa ʻana i ka corrosion intergranular ma mua o ke kila kila 304. Ma waho aʻe o ka ikaika haʻahaʻa iki, ʻo nā waiwai ʻē aʻe me ke kila kila 321, i hoʻohana nui ʻia no nā lako a me nā ʻāpana e kūʻē i ka corrosion ʻaʻole hiki ke hoʻopili ʻia me ka hopena lapaʻau, hiki ke hoʻohana ʻia no ka hana ʻana i nā ʻano kino instrumentation like ʻole.

3.304H kila kila. 304 lālā kila kila kila, ʻo ka hapa nui kalapona he 0.04% ~ 0.10%, ʻoi aku ka maikaʻi o ka hana wela kiʻekiʻe ma mua o 304 kila kila kila.

4.316 kila kila. I loko o ke kila 10Cr18Ni12 e pili ana i ka hoʻohui ʻana o ka molybdenum, i loaʻa i ke kila ke kūpaʻa maikaʻi i ka hōʻemi ʻana i ka media a me ke kūpaʻa ʻana i ka palaho. I loko o ka wai kai a me nā media ʻē aʻe, ʻoi aku ka maikaʻi o ke kūpaʻa ʻana i ka palaho ma mua o ke kila kila 304, hoʻohana nui ʻia no ka pitting corrosion i nā mea kūʻē i ka palaho.

5.316L kila kila. ʻO ke kila kalapona haʻahaʻa loa, me ke kūpaʻa maikaʻi i ka pala intergranular sensitized, kūpono no ka hana ʻana i ka nui o ka ʻāpana keʻa o nā ʻāpana i hoʻopaʻa ʻia a me nā lako, e like me nā lako petrochemical i nā mea kūpaʻa i ka pala.

6.316H kila kila. lālā kūloko o ke kila kila kila 316, ʻo ka hapa nui kalapona he 0.04%-0.10%, ʻoi aku ka maikaʻi o ka hana wela kiʻekiʻe ma mua o ke kila kila 316.

7.317 kila kila. ʻOi aku ka maikaʻi o ke kūpaʻa ʻana i ka pitting corrosion a me ke kūpaʻa kolo ma mua o ke kila kila 316L, i hoʻohana ʻia i ka hana ʻana i nā lako hana kūpaʻa petrochemical a me nā waikawa organik.

8.321 kila kila. ʻO ke kila kila austenitic paʻa titanium, me ka hoʻohui ʻana i ka titanium e hoʻomaikaʻi i ke kūpaʻa ʻana i ka corrosion intergranular, a he mau waiwai mechanical maikaʻi kona, hiki ke pani ʻia e ke kila kila austenitic kalapona haʻahaʻa loa. Ma waho aʻe o ke kūpaʻa ʻana i ka wela kiʻekiʻe a i ʻole ka hydrogen corrosion a me nā hanana kūikawā ʻē aʻe, ʻaʻole ʻōlelo ʻia ke kūlana maʻamau.

9.347 kila kila. Hoʻopaʻa ʻia ke kila kila austenitic niobium, hoʻohui ʻia ka niobium e hoʻomaikaʻi i ke kūʻē ʻana i ka corrosion intergranular, kūpaʻa i ka corrosion i ka waikawa, alkali, paʻakai a me nā mea corrosive ʻē aʻe me ke kila kila 321, hana maikaʻi ka hoʻopili ʻana, hiki ke hoʻohana ʻia e like me nā mea kūʻē i ka corrosion a me ke kila kūʻē i ka wela i hoʻohana nui ʻia no ka mana wela, nā kahua petrochemical, e like me ka hana ʻana o nā ipu, nā pipelines, nā mea hoʻololi wela, nā ʻauamo, nā umu ʻoihana i loko o ka paipu umu a me ka thermometer paipu umu a pēlā aku.

10.904L kila kila. ʻO ke kila kila austenitic piha loa, he kila kila austenitic super i hana ʻia e Finland Otto Kemp, ʻo kona hapa nui nickel he 24% a 26%, ʻo ka hapa nui kalapona ma lalo o 0.02%, kūpaʻa maikaʻi loa i ka pala, i loko o nā waikawa non-oxidizing e like me ka sulfuric, acetic, formic a me ka phosphoric acid he kūpaʻa maikaʻi loa i ka pala, a i ka manawa like he kūpaʻa maikaʻi i ka pala crevice a me ke kūpaʻa i nā waiwai pala stress. He kūpono ia no nā ʻano like ʻole o ka waikawa sulfuric ma lalo o 70 ℃, a he kūpaʻa maikaʻi i ka pala i ka waikawa acetic a me ka waikawa hui o ka waikawa formic a me ka waikawa acetic o kekahi ʻano a me kekahi mahana ma lalo o ke kaomi maʻamau. ʻO ke kūlana mua ASMESB-625 e pili ana iā ia i nā mea hoʻohuihui nickel, a ʻo ke kūlana hou e pili ana iā ia i ke kila kila. ʻO Kina wale nō ke kila ma kahi o 015Cr19Ni26Mo5Cu2, a ʻo kekahi mau mea hana mea kani ʻEulopa e hoʻohana ana i ke kila kila 904L no nā mea nui, e like me ke ana ʻana o ka paipu ana o ka mika kahe nui o E + H e hoʻohana ana i ke kila kila 904L, a hoʻohana pū ʻia ka hihia uaki Rolex i ke kila kila 904L.

11.440C kila kila. Ke kila kila Martensitic, ke kila kila paʻakikī, ke kila kila ma ka paʻakikī kiʻekiʻe loa, ka paʻakikī HRC57. Hoʻohana nui ʻia i ka hana ʻana o nā nozzles, bearings, valves, spools valve, noho valve, sleeves, valves stems, etc.

12.17-4PH kila kila. ʻO ke kila kila paʻakikī Martensitic precipitation, paʻakikī HRC44, me ka ikaika kiʻekiʻe, paʻakikī a me ke kūpaʻa i ka pala, ʻaʻole hiki ke hoʻohana ʻia no nā mahana kiʻekiʻe ma mua o 300 ℃. Loaʻa iā ia ke kūpaʻa maikaʻi i ka pala i nā waikawa lewa a me nā waikawa dilute a i ʻole nā paʻakai, a ʻo kona kūpaʻa i ka pala e like me ke kila kila 304 a me ke kila kila 430, i hoʻohana ʻia i ka hana ʻana i nā kahua kai, nā lau turbine, nā spools, nā noho, nā lima a me nā kumu o nā valves.

I ka ʻoihana mea hana, me ka laulā a me nā pilikia kumukūʻai, ʻo ke kauoha koho kila kila austenitic maʻamau ʻo 304-304L-316-316L-317-321-347-904L kila kila, ʻo 317 ka mea i hoʻohana pinepine ʻole ʻia, ʻaʻole ʻōlelo ʻia ʻo 321, hoʻohana ʻia ʻo 347 no ka pala wela kiʻekiʻe, ʻo 904L wale nō ka mea maʻamau o kekahi mau ʻāpana o nā mea hana pākahi, ʻaʻole e lawe ka hoʻolālā i ka hana mua e koho i ka 904L.

I ke koho ʻana i ka hoʻolālā mea hana, e loaʻa pinepine nā mea hana a me nā mea paipu i nā manawa like ʻole, ʻoiai i nā kūlana wela kiʻekiʻe. Pono mākou e hoʻolohe pono i ke koho ʻana i nā mea hana e hoʻokō ai i ka mahana o ka hana a i ʻole ke kaomi o ka hoʻolālā ʻana o ka pipeline, e like me ke kiʻekiʻe wela o ka pipeline kila chrome molybdenum, ʻoiai ke koho ʻana i ke kila kila no nā mea hana, a laila he pilikia nui ia. Pono ʻoe e nīnau i ke ana wela a me ke ana kaomi e pili ana i nā mea hana.

I ke koho ʻana i ka hoʻolālā mea kani, pinepine ʻia nā ʻano ʻōnaehana like ʻole, nā moʻo, a me nā papa o ke kila kila, pono ke koho ʻana ma muli o ke kaʻina hana kikoʻī, ka mahana, ke kaomi, nā ʻāpana i hoʻokaumaha ʻia, ka pala a me ke kumukūʻai a me nā manaʻo ʻē aʻe.

Ka manawa hoʻouna: ʻOkakopa-11-2023