Nā Papa Mea a me ka Hoʻokō ʻana me nā Kūlana Honua

Hana ʻo Womic Steel i nā flanges kila kila me ka hoʻohana ʻana i nā mea maka maikaʻi loa i loaʻa mai nā mea hoʻolako honua i hōʻoia ʻia. ʻO nā ʻano mea maʻamau i loaʻa:

- Nā Papa AISI/ASTM: 304, 304L, 304H, 316, 316L, 316Ti, 321, 317L, 310S, 904L

- Duplex a me Super Duplex: S31803, S32205, S32750, S32760

- Nā ʻAla Nikala (ma ke noi ʻana): ʻAla Nikala 20, Hastelloy C276, Inconel 625

Hoʻokō pono kā mākou mau flanges kila kila i nā kūlana honua e like me:

1. ASME/ANSI B16.5, B16.47 (Moʻo A & B), B16.36, B16.48

2. ASTM A182 (Hoʻoheheʻe ʻia), A240 (Palapala), A351 (Hoʻolei ʻia)

3. EN 1092-1 / EN 1092-2

4. DIN 2631 a i DIN 2635

5. JIS B2220, BS 4504, GOST 33259, a me ISO 7005

Hiki iā Womic Steel ke hana i nā flanges i nā kiʻi kikoʻī a ka mea kūʻai aku a me nā kikoʻī papahana (OEM/ODM).

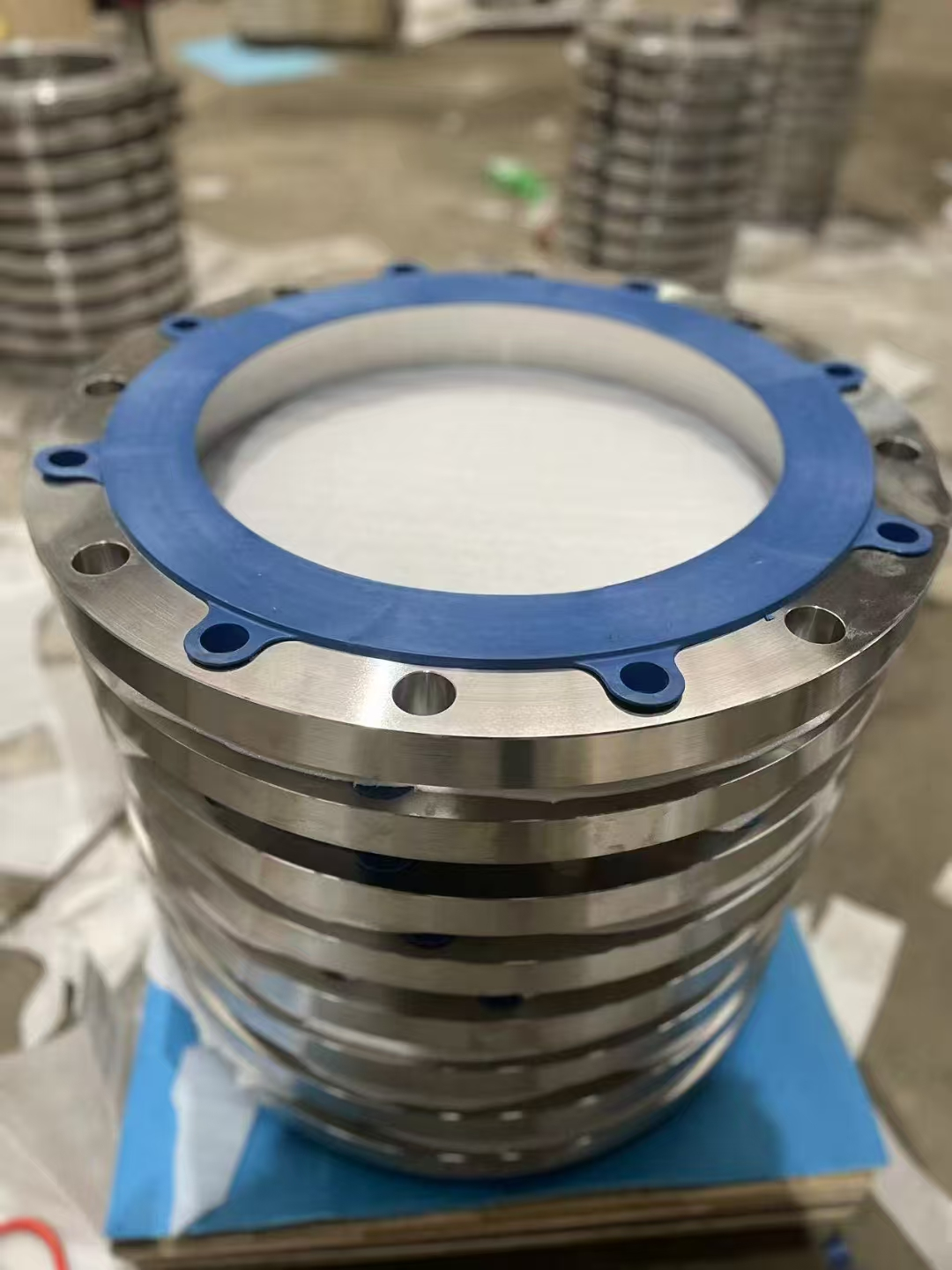

Nā ʻAno Flange a me ka Pae Dimensional

Hana ʻo Womic Steel i kahi laulā piha o nā ʻano flange kila kila, kūpono no nā papa kaomi mai ka Papa 150 a i ka Papa 2500 a me PN6 a i PN100.

Nā ʻAno Flange Maʻamau:

1. Weld Neck Flange (WN)

2. ʻO ka Flange Paheʻe (SO)

3. ʻO ka Flange Makapō (BL)

4. Socket Weld Flange (SW)

5. Flange Wili (TH)

6. Lap Joint Flange (LJ)

7. Orifice Flange, Long Weld Neck, Spectacle Blind, Hoʻemi i ka Flange

Ka laulā nui:

- ASME/ANSI: ½” a i 60”

- EN/DIN: DN10 a i DN1600

- Mānoanoa: SCH10S a i SCH160 / XXS

- Hana mīkini i hoʻopilikino ʻia: a hiki i ka 120” ke anawaena o waho i loaʻa

Nā Koina Kemika a me nā Mekanika (Laʻana: ASTM A182 F316L)

C ≤ 0.03, Mn ≤ 2.00, Si ≤ 1.00, Cr: 16.0–18.0, Ni: 10.0–14.0, Mo: 2.0–3.0

Hoʻāʻo ʻia nā mea maka e hiki mai ana a pau i ka PMI a ua hōʻoia ʻia ka hiki ke hahai ʻia ka wela ma ka hana ʻana.

Nā Waiwai Mekanika a me nā Koina Hopena

Hōʻoia ʻo Womic Steel i kēlā me kēia flange e hoʻokō a ʻoi aku paha ma mua o nā kūlana mechanical e like me nā kikoʻī ASTM a i ʻole EN:

- Ikaika Tensile: ≥ 485 MPa (F316L)

- Ikaika Hua (0.2% offset): ≥ 170 MPa

- Elongation: ≥ 30%

- Paʻakikī: ≤ 90 HRB

- Hoʻāʻo Hopena Charpy V-Notch: Loaʻa ma -20°C, -46°C, a i ʻole ka mahana kikoʻī o ka papahana

Loaʻa nā palapala hōʻoia hoʻāʻo mīkini maʻamau (EN 10204 3.1 / 3.2).

Kaʻina Hana a me ka Hoʻomehana ʻana

- Ke hana ʻana - ʻO ka ʻaukā maka a i ʻole ka billet i hana ʻia i ke ʻano me ka mīkini paʻi hydraulic

2. Ka Lapaʻau Wela - Hoʻomaʻamaʻa ʻana a i ʻole ka hoʻoheheʻe ʻana i ka hopena e like me nā kikoʻī mea

3. Machining - Hōʻoia nā mīkini CNC i ka palahalaha, ke ahonui, a me ka hoʻopau ʻana o ka maka sila (RF, RTJ, FF, MF, TG)

4. ʻEli ʻana - Pōʻai lua bolt e like me ke kūlana maʻamau a i ʻole ka kikoʻī o ka mea kūʻai aku

5. Māka - Laser a i ʻole i hoʻopaʻa ʻia me ke anu me ka papa, ka nui, ka helu wela, ke kūlana, a me ka logo

6. Pickling & Passivation - Hōʻoia i ke kūpaʻa ʻana i ka pala a me ka hoʻopau maʻemaʻeNā kaʻina hana kūikawā koho: Loaʻa ka uhi ʻana o ka ʻili HVOF, ka hoʻāʻo cryogenic, a i ʻole ka hoʻopili ʻana i ka wili ʻana ma ke noi. Hoʻolohe nui mākou i ka sila ʻana i ka ʻoʻoleʻa o ka maka (maʻamau 3.2–6.3 μm Ra) e hōʻoia i ka hana gasket maikaʻi loa.

Hoʻāʻo a me ka Mana Kūlana

Hana ʻia nā flanges āpau i ka nānā piha ʻana me nā hoʻolālā hoʻāʻo pākahi (ITPs). ʻO nā hoʻāʻo koʻikoʻi:

- Nānā ʻIke a me ke Ana (100%)

- Hoʻāʻo Hydrostatic (no nā ʻaha kūkā)

- PMI (ʻIke Mea Maikaʻi)

- Hoʻāʻo Ultrasonic (UT) ma nā forgings

- Hoʻāʻo Penetrant Dye (PT)

- Hoʻāʻo Radiographic (RT) ma ke noi ʻana

- Hoʻāʻo paʻakikī a me ka hopena

- Nānā ʻana i ka ʻOʻoleʻa o ka ʻIli

Mālama ʻia ka hiki ke huli piha ʻia me ka Heat No. a me ka Batch ID kū hoʻokahi.

Nā Palapala Hōʻoia

- ʻŌnaehana Hoʻokele Kūlana ISO 9001:2015

- PED 2014/68/EU Pressure Equipment Directive (hōʻailona CE)

- AD 2000-W0, EN 10204 3.1 / 3.2

- Nā palapala hōʻoia DNV, BV, LR, ABS, a me TÜV ma ke noi ʻana

Kūlike nā mea āpau me NACE MR0175 / ISO 15156 inā pono no ka lawelawe ʻawaʻawa.

Nā noi

Ua hoʻolālā ʻia nā flanges kila kila o Womic Steel no:

- Nā Paipu ʻAila a me ke Kinoea

- Petrochemical a me nā hale hana hoʻomaʻemaʻe

- Nā Hale Hana Hoʻōla Wai

- Hana ʻana i nā lāʻau lapaʻau a me ka meaʻai

- Nā Mea Hana Mana a me nā ʻōnaehana Boiler

- Nā Hale Hoʻonohonoho Moana a me nā Hale Hoʻonohonoho Ma waho o ke Kai

- Nā ʻōnaehana kinai ahi, HVAC, a me nā ʻōnaehana hoʻoluʻu ʻāpanaA pēlā aku.

Ka Manawa Alakaʻi Hana & Ka Hoʻopili ʻana

Ka manawa o waena o ka hoʻomaka a i ka wā pau:

- Nā mea waihona: 5–7 lā

- Hana maʻamau: 15–25 mau lā

- Hana maʻamau/mīkini: 30–45 mau lā ma muli o ka paʻakikī

Pūʻolo:

- Nā hihia plywood a i ʻole nā pallets hoʻokuʻu aku i ke kai

- Nā pāpale palaki no ka sila ʻana i nā maka

- PE wrap, ʻaila kūlike, a me nā ʻeke desiccant e pale aku i ka pala

- Loaʻa ka barcode pākahi a me ka māka pallet

Logistics & Transport

Hāʻawi ʻo Womic Steel i ka hoʻonohonoho logistics ikaika a me nā pono hoʻouna:

- Hoʻopiha ipu me nā hoʻolālā hoʻouka kūpono

- Hoʻouna ʻia i nā wahi i manaʻo ʻia e CIF/CFR/DDP

- ʻO ka laulima pololei me nā laina hoʻouna e hōʻoiaʻiʻo i nā kumukūʻai ukana hoʻokūkū

- Hoʻoikaika ʻia ka ʻōpala no nā flanges kaumaha me ka pale ʻana o loko a me nā ʻāpana kila

Nā lawelawe hoʻopilikino a me ka hana ʻana

Hāʻawi kā mākou hale hana mīkini i loko o ka hale:

- CNC huli, alo, a me ka wili ʻana

- Ka hana ʻana i ka mīkini sila maka maʻamau (RTJ, serrated, flat)

- Kuʻihao a me ke kāpili ʻana (mai ke kila kila a i ke kalapona)

- Ke kaula ʻana (NPT/BSPT/BSPP)

- Nā kiʻi maʻamau a me ke kākoʻo CAD

- Ka hoʻopili ʻana a me ka hana ʻana i ka maʻemaʻe kiʻekiʻe no nā flanges sanitary

- Ka lapaʻau ʻaila passivation a me ka anti-corrosion

No ke aha e koho ai iā Womic Steel?

1. Ma luna o 15,000 tons ka mana hana makahiki

2. Ka palapala piha no ka hiki ke hahai i nā mea a me ka nānā ʻana

3. Loaʻa wikiwiki nā mea maka mai nā mea kūʻai waiwai koʻikoʻi

4. Nā hoʻonā i hoʻopilikino ʻia me nā manawa alakaʻi pōkole

5. Keʻena hoʻokolohua mīkini holomua a me ka hoʻāʻo ʻana i loko o ka hale

6. ʻIke hoʻokuʻu honua a me nā kuhikuhi papahana

Kāhea iā mā˚ou

No kāu papahana aʻe, e hilinaʻi iā Womic Steel e hāʻawi i nā flanges kila kila i hana ʻia me ka pololei me ka lawe wikiwiki a me ke kākoʻo loea piha.

Pūnaewele: www.womicsteel.com

Leka uila: sales@womicsteel.com

Kelepona/WhatsApp/WeChat: Victor: +86-15575100681 a i ʻole Jack: +86-18390957568

Ka manawa hoʻouna: ʻApelila-19-2025