Hoʻolauna:

ʻO API 5L kahi kikoʻī maʻamau i hoʻokumu ʻia e ka American Petroleum Institute (API) no nā paipu kila seamless a welded i hoʻohana ʻia i nā ʻōnaehana halihali i loko o nā ʻoihana petroleum a me ke kinoea kūlohelohe. ʻO Womic Steel, kahi mea hana alakaʻi o nā paipu laina API 5L, hāʻawi i kahi laulā piha o nā huahana e hoʻokō i nā papa like ʻole a me nā kikoʻī. Hāʻawi kēia ʻatikala i kahi hoʻohālikelike kikoʻī o ka haku mele kemika, nā waiwai mechanical, a me nā kūlana hoʻāʻo no nā papa API 5L like ʻole, ʻo PSL1 a me PSL2 ma waena o ʻekolu ʻano paipu: ERW (Electric Resistance Welded), LSAW (Longitudinal Submerged Arc Welded), a me SMLS (Seamless).

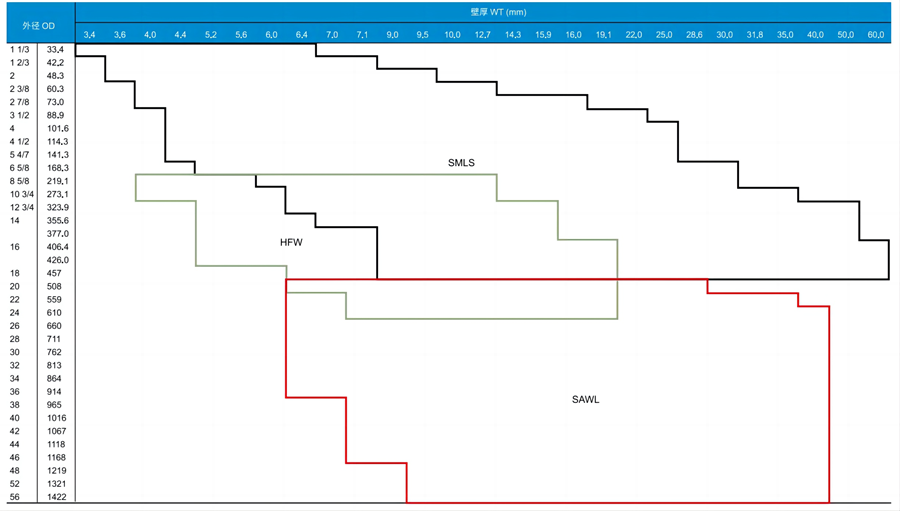

Ka Mana Hana a me ka Laulā:

| 制造方法 | 钢级起 | 钢级止 | 外径起 OD Min mm | 外径止 | 壁厚起 | 壁厚止 | 生产能力 |

| Nā SMLS | B | X80Q | 33.4 | 457 | 3.4 | 60 | 200000 |

| HFW | B | X80M | 219.1 | 610 | 4.0 | 19.1 | 200000 |

| SAWL | B | X100M | 508 | 1422 | 6.0 | 40 | 500000 |

Ka hoʻomanawanui o ke anawaena o waho

| 标准 | 外径范围 | 外径公差 | 椭圆度 | ||||

| 管体 | 管端 | 管体 | 管端 | ||||

| 无缝 | 焊管 | 无缝 | 焊管 | 无缝 | 焊管 | ||

| API SPEC SO 3183 | D<60.3mm | +0.4mm/-0.8mm | +1.6mm/-0.4mm | ||||

| 60.3mm≤D≤168.3mm | +0.75%/-0.75% | ≤2.0% | ≤1.5% | ||||

| 168.3mm | +0.5%/-0.5% | ||||||

| 320mm | +1.6mm/-1.6mm | ||||||

| 426mm | +0.75%/-0.75% | +3.2mm/-3.2mm | |||||

| 610mm | +1.0%/-1.0% | +0.5%/-0.5% | ±2.0mm | ±1.6mm | ≤1.5% | ≤1.0% | |

| 800mm | +4mm/-4mm | ||||||

| 1000mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤1.0% | |||

| 1300mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤13mm | |||

Nānā: ʻO D ke anawaena waho maʻamau o ka paipu.

Ka hoʻomanawanui o ka mānoanoa o ka paia

| 标准 | 外径范围 | 壁厚范围 | 壁厚公差 | 壁厚公差 |

| 无缝 | 焊管 | |||

| API SPEC ISO 3183 | - | t≤4.0mm | +0.6mm/-0.5mm | +0.5mm/-0.5mm |

| - | 4.0mm | +15%/-12.5% | ||

| - | 5.0mm | +10%/-10% | ||

| - | 15.0mmst<25.0mm | +1.5mm/-1.5mm | ||

| - | 25.0mm≤t<30.0mm | +3.7mm/-3.0mm | ||

| - | 30.0mm≤t<37.0mm | +3.7mm/-10.0% | ||

| - | t≥37.0mm | +10.0%/-10.0% |

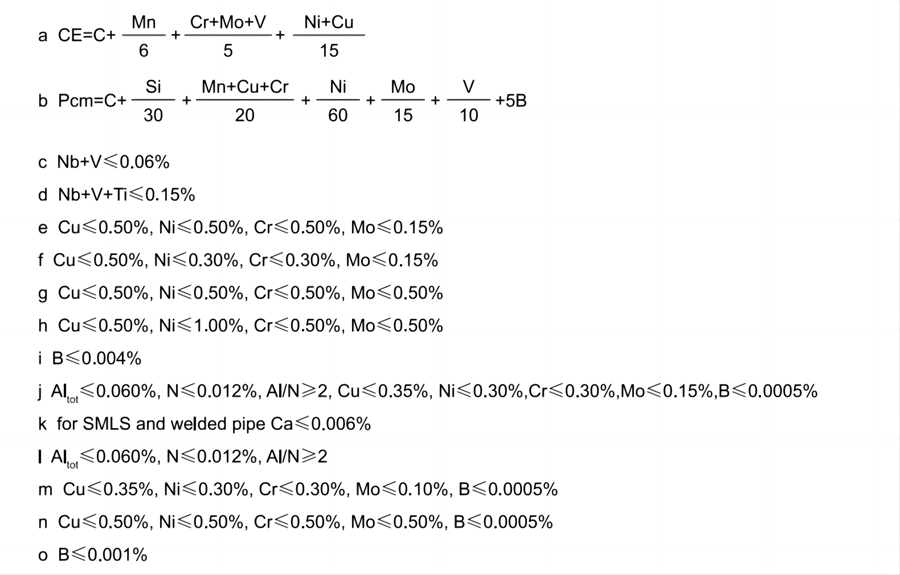

Ka Nānā Kemika

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CE | Pcm | 备注 |

| ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | |||||

| API SPEC 5L | 无缝管 | PSL1 | L210 a i ʻole A | 0.22 |

| 0.90 | 0.030 | 0.030 |

|

|

|

|

| e,o |

| L245 a i ʻole B | 0.28 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| c,d,e,o | |||

| L290 a i ʻole X42 | 0.28 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L320 a i ʻole X46 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 a i ʻole X52 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 a i ʻole X56 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 a i ʻole X60 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 a i ʻole X65 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| ka,o | |||

| L485 a i ʻole X70 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | L245N a i ʻole BN | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 |

|

| 0.04 | 0.43 | 0.25 | c,f,o | ||

| L290N a i ʻole X42N | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320N a i ʻole X46N | 0.24 | 0.40 | 1.40 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L360N a i ʻole X52N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L390N a i ʻole X56N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415N a i ʻole X60N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | E like me ka ʻaelike | d,g,o | ||||

| L245Q a i ʻole BQ | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L290Q a i ʻole X42Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320Q a i ʻole X46Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| 13600 a i ʻole ×52Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L390Q a i ʻole X56Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415Q a i ʻole X60Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L450Q a i ʻole X65Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485Q a i ʻole X70Q | 0.18 | 0.45 | 1.80 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L555Q a i ʻole X80Q | 0.18 | 0.45 | 1.90 | 0.025 | 0.015 |

|

|

| E like me ka ʻaelike | Hui | ||||

| 酸性服 | L245NS a i ʻole BNS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 |

|

| 0.04 | 0.36 | 0.22 | c,d,j,k | ||

| ʻO L290NS a i ʻole X42NS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | j,k | |||

| L320NS a i ʻole X46NS | 0.14 | 0.40 | 1.40 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | dj,k | |||

| ʻO L360NS a i ʻole X52NS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,j,k | |||

| L245QS a i ʻole BQS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L290QS a i ʻole X42QS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L320QS a i ʻole X46QS | 0.15 | 0.45 | 1.40 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | j,k | |||

| L360QS a i ʻole X52QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,j,k | |||

| L390QS a i ʻole X56QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,j,k | |||

| L415QS a i ʻole X60QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | dj,k | |||

| L450QS a i ʻole X65QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| L485QS a i ʻole X70QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | Ti | CEa | Pcm | 备注 |

| ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | |||||

| AP|SPEC 5L | 无缝管 | 海上服 | L245NO a i ʻole BNO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 |

|

| 0.04 | 0.36 | 0.22 | c,d,i,m |

| L290NO a i ʻole X42NO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | l,m | |||

| L320NO a i ʻole X46NO | 0.14 | 0.40 | 1.40 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | d,ʻO wau,m | |||

| L360NO a i ʻole X52NO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,ʻO wau | |||

| L245QO a i ʻole BQO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L290QO a i ʻole X42Q0 | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L320QO a i ʻole X46QO | 0.15 | 0.45 | 1.40 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | l,m | |||

| L360QO a i ʻole X52QO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,I,n | |||

| L390QO a i ʻole X56Q0 | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,I,n | |||

| L415QO a i ʻole X60QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | d,I,n | |||

| L455QO a i ʻole X65QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,I,n | |||

| L485Q0 a i ʻole X70Q0 | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | 0.42 | 0.25 | d,l,n | |||

| L555QO a i ʻole X80QO | 0.17 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.06 | 0.06 | E like me ka ʻaelike | d,I,n | ||||

| 焊管 | PSL1 | L245 a i ʻole B | 0.26 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| cd,e,c | |

| L290 a i ʻole X42 | 0.26 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L320 a i ʻole X46 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 a i ʻole X52 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 a i ʻole X56 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 a i ʻole X60 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 a i ʻole X65 | 0.26 |

| 1.45 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L485 a i ʻole X70 | 0.26 |

| 1.65 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | 1245M a i ʻole BM | 0.22 | 0.45 | 1.20 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | ||

| L290M a i ʻole X42M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320M a i ʻole X46M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L360M a i ʻole X52M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L390M a i ʻole X56M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L415M a i ʻole X60M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L450M a i ʻole X65M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485M a i ʻole X70M | 0.12 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L555M a i ʻole X80M | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CEa | Pcm | 备注 |

| ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | ka nui loa | |||||

| API SPEC 5L | 焊管 | 酸性服 | L245MS a i ʻole BMS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k |

| L290MS a i ʻole X42MS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k | |||

| L320MS a i ʻole X46MS | 0.10 | 0.45 | 1.35 | 0.020 | 0.002 | 0.05 | 0.05 | 0.04 |

| 0.20 | j,k | |||

| L360MS a i ʻole X52MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.05 | 0.06 | 0.04 |

| 0.20 | j,k | |||

| L390MS a i ʻole X56MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,j,k | |||

| L415MS a i ʻole X60MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,j,k | |||

| L450MS a i ʻole X65MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,j,k | |||

| L485MS a i ʻole X70MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | dj,k | |||

| 海上服 | L245MO a i ʻole BMO | 0.12 | 0.40 | 1.25 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | ||

| L290MO a i ʻole X42MO | 0.12 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | |||

| L320MO a i ʻole X46MO | 0.12 | 0.45 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | ʻO wau,m | |||

| L360MO a i ʻole X52MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | d,I,n | |||

| L390MO a i ʻole X56MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,l,n | |||

| L415MO a i ʻole X60MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,I,n | |||

| L450MO a i ʻole X65MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.222 | d,I,n | |||

| L485MO a i ʻole X70MO | 0.12 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,l,n | |||

| L555MO a i ʻole X80MO | 0.12 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.24 | d,I,n |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| API SPEC 5L | PSL1 | L210 a i ʻole A | Min | 210 | 335 | a |

| 335 |

| L245 a i ʻole B | Min | 245 | 415 | a |

| 415 | ||

| L290 a i ʻole X42 | Min | 290 | 415 | a |

| 415 | ||

| L320 a i ʻole X46 | Min | 320 | 435 | a |

| 435 | ||

| L360 a i ʻole X52 | Min | 360 | 460 | a |

| 460 | ||

| L390 a i ʻole X56 | Min | 390 | 490 | a |

| 490 | ||

| L415 a i ʻole X60 | Min | 415 | 520 | a |

| 520 | ||

| L450 a i ʻole X65 | Min | 450 | 535 | a |

| 535 | ||

| L485 a i ʻole X70 | Min | 485 | 570 | a |

| 570 | ||

| PSL2 | L245N a i ʻole BN | Min | 245 | 415 | a |

| 415 | |

| Max | 450 | 655 |

| 0.93 |

| |||

| L290N a i ʻole X42N | Min | 290 | 415 | a |

| 415 | ||

| Max | 495 | 655 |

| 0.93 |

| |||

| L320N a i ʻole X46N | Min | 320 | 435 | a |

| 435 | ||

| Max | 525 | 655 |

| 0.93 |

| |||

| L360N a i ʻole X52N | Min | 360 | 460 | a |

| 460 | ||

| Max | 530 | 760 |

| 0.93 |

| |||

| L390N a i ʻole X56N | Min | 390 | 490 | a |

| 490 | ||

| Max | 545 | 760 |

| 0.93 |

| |||

| L415N a i ʻole X60N | Min | 415 | 520 | a |

| 520 | ||

| Max | 565 | 760 |

| 0.93 |

| |||

| L450Q a i ʻole X65Q | Min | 450 | 535 | a |

| 535 | ||

| Max | 600 | 760 |

| 0.93 |

| |||

| L485Q a i ʻole X70Q | Min | 485 | 570 | a |

| 570 | ||

| Max | 635 | 760 |

| 0.93 |

| |||

| L555Q a i ʻole X80Q | Min | 555 | 625 | a |

| 625 | ||

| Max | 705 | 825 |

| 0.93 |

| |||

| L625M a i ʻole X90M | Min | 625 | 695 | a |

| 695 | ||

| Max | 775 | 915 |

| 0.95 |

| |||

| L690M a i ʻole X100M | Min | 690 | 760 | a |

| 760 | ||

| Max | 840 | 990 |

| 0.97 |

| |||

| L830M a i ʻole X120M | Min | 830 | 915 | a |

| 915 | ||

| Max | 1050 | 1145 |

| 0.99 |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| API SPEC 5L | 酸性服 | L245NS a i ʻole BNS | Min | 245 | 415 | a |

| 415 |

| Max | 450 | 655 |

| 0.93 |

| |||

| ʻO L290NS a i ʻole X42NS | Min | 290 | 415 | a |

| 415 | ||

| Max | 495 | 655 |

| 0.93 |

| |||

| L320NS a i ʻole X46NS | Min | 320 | 435 | a |

| 435 | ||

| Max | 525 | 655 |

| 0.93 |

| |||

| ʻO L360NS a i ʻole X52NS | Min | 360 | 460 | a |

| 460 | ||

| Max | 530 | 760 |

| 0.93 |

| |||

| L390QS a i ʻole X56QS | Min | 390 | 490 | a |

| 490 | ||

| Max | 545 | 760 |

| 0.93 |

| |||

| L415QS a i ʻole X60QS | Min | 415 | 520 | a |

| 520 | ||

| Max | 565 | 760 |

| 0.93 |

| |||

| L450QS a i ʻole X65QS | Min | 450 | 535 | a |

| 535 | ||

| Max | 600 | 760 |

| 0.93 |

| |||

| L485QS a i ʻole X70QS | Min | 485 | 570 | a |

| 570 | ||

| Max | 635 | 760 |

| 0.93 |

| |||

| 海上服 | L245NO a i ʻole BNO | Min | 245 | 415 | a | - | 415 | |

| Max | 450 | 655 |

| 0.93 |

| |||

| L290NO a i ʻole X42NO | Min | 290 | 415 | a |

| 415 | ||

| Max | 495 | 655 |

| 0.93 |

| |||

| L320NO a i ʻole X46NO | Min | 320 | 435 | a |

| 435 | ||

| Max | 520 | 655 |

| 0.93 |

| |||

| L360NO a i ʻole X52NO | Min | 360 | 460 | a |

| 460 | ||

| Max | 525 | 760 |

| 0.93 |

| |||

| L390QO a i ʻole X56QO | Min | 390 | 490 | a |

| 490 | ||

| Max | 540 | 760 |

| 0.93 |

| |||

| L415QO a i ʻole X60QO | Min | 415 | 520 | a | - | 520 | ||

| Max | 565 | 760 |

| 0.93 |

| |||

| L450QO a i ʻole X65QO | Min | 450 | 535 | a | - | 535 | ||

| Max | 570 | 760 |

| 0.93 |

| |||

| L485Q0 a i ʻole X70Q0 | Min | 485 | 570 | a |

| 570 | ||

| Max | 605 | 760 |

| 0.93 |

| |||

| L555QO a i ʻole X80QO | Min | 555 | 625 | a |

| 625 | ||

| Max | 675 | 825 |

| 0.93 |

Nānā: a: ʻO ka elongation liʻiliʻi loa me ka hoʻohana ʻana i ka hoohalike aʻe: A1=1940*A0.2/U0.9

| 钢级 | 管体最小横向冲击功(1(2)(3) | 焊缝最小横向冲击功(1(2(3) | |||||

| D≤508 | 508mm | 762mm | 914mm | 1219mm | D<1422mm | D=1422mm | |

| ≤L415 a i ʻole X60 | 27(20) | 27(20) | 40(30) | 40(30) | 40(30) | 27(20) | 40(30) |

| >L415 a i ʻole X60 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L450 a i ʻole X65 | 27(20) | 27(20) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

| >L485 a i ʻole X70 | 40(30) | 40(30) | 40(30) | 40(30) | 54(40) | 27(20) | 40(30) |

Nānā: (1) E kūpono nā waiwai ma ka papa no ka laʻana maʻamau piha.

(2) ʻO ka waiwai i loko o ka bracket ka waiwai hoʻokahi haʻahaʻa loa, ʻo ka bracket waho ka waiwai awelika.

(3) Mahana Hoʻāʻo: 0°C.

Nā Kūlana Hoʻāʻo:

Hoʻāʻo pono ʻia nā paipu laina API 5L i hana ʻia e Womic Steel e hōʻoia i ko lākou hoʻokō ʻana i nā kūlana kiʻekiʻe loa. ʻO nā kūlana hoʻāʻo:

Ka Nānā Kemika:

Ua kālailai ʻia ka haku mele kemika o ke kila e hōʻoia i kona hoʻokō ʻana i nā koi o ka kikoʻī API 5L.

Hana ʻia ka loiloi kemika me ka hoʻohana ʻana i kahi spectrometer heluhelu pololei e hoʻoholo pololei i ka haku mele ʻana o ke kila.

Hoʻāʻo Mīkini:

Hoʻāʻo ʻia nā waiwai mīkini e like me ka ikaika yield, ka ikaika tensile, a me ka elongation e hōʻoia i ko lākou hoʻokō ʻana i nā koi i kuhikuhi ʻia.

Hana ʻia ka hoʻāʻo ʻana o ka mīkini me ka hoʻohana ʻana i kahi mīkini hoʻāʻo tensile 60-tona e ana i ka ikaika a me ka ductility o ke kila.

Hoʻāʻo Hydrostatic:

Hana ʻia ka hoʻāʻo hydrostatic e nānā i ka pono o ka paipu a hōʻoia i hiki iā ia ke kū i nā koi kaomi o kāna noi i manaʻo ʻia.

Hoʻopiha ʻia nā paipu me ka wai a kau ʻia i ke kaomi, me ka lōʻihi o ka hoʻāʻo a me nā pae kaomi i kuhikuhi ʻia e nā kūlana API 5L.

Hoʻāʻo ʻAʻole Luku (NDT):

Hoʻohana ʻia nā ʻano NDT e like me ka hoʻāʻo ultrasonic (UT) a me ka hoʻāʻo ʻana i nā ʻāpana magnetic (MT) e ʻike i kekahi mau hemahema a i ʻole nā discontinuities i loko o ka paipu.

Hoʻohana ʻia ʻo UT e ʻike i nā hemahema kūloko, ʻoiai hoʻohana ʻia ʻo MT e ʻike i nā hemahema o ka ʻili.

Hoʻāʻo hopena:

Hana ʻia ka hoʻāʻo hopena e loiloi i ka paʻakikī o ke kila ma nā mahana haʻahaʻa.

Hoʻohana pinepine ʻia ka hoʻāʻo hopena Charpy e ana i ka ikehu hopena i omo ʻia e ke kila.

Hoʻāʻo Paʻakikī:

Hana ʻia ka hoʻāʻo paʻakikī e loiloi i ka paʻakikī o ke kila, hiki ke hōʻike i kona ikaika a me ke kūpono no nā noi kikoʻī.

Hoʻohana pinepine ʻia ka hoʻāʻo paʻakikī ʻo Rockwell e ana i ka paʻakikī o ke kila.

Ka Hoʻokolokolo ʻana o ka Microstructure:

Hana ʻia ka hoʻokolokolo ʻana o ka microstructure e loiloi i ke ʻano o ka palaoa a me ka maikaʻi holoʻokoʻa o ke kila.

Hoʻohana ʻia kahi microscope metallurgical e nānā i ka microstructure o ke kila a ʻike i nā mea ʻē.

Ma ka pili ʻana i kēia mau kūlana hoʻāʻo koʻikoʻi, hōʻoia ʻo Womic Steel e hoʻokō ana kāna mau paipu laina API 5L i nā koi kūlana kiʻekiʻe loa a hāʻawi i ka hana hilinaʻi ma nā ʻano hana ʻoihana like ʻole.

Kaʻina Hana:

1. Nā Paipu Kila Hana ʻOle:

- Koho Mea Maka: Ua koho ʻia nā bila kila poepoe kiʻekiʻe no ka hana ʻana i nā paipu kila humuhumu ʻole.

- Hoʻomehana a me ke hou ʻana: Hoʻomehana ʻia nā billets i kahi mahana kiʻekiʻe a laila hou ʻia e hana i kahi pūpū hakahaka.

- Ka ʻōwili ʻana a me ka nui ʻana: A laila ʻōwili ʻia ka pūpū i hou ʻia a kīkoʻo ʻia i ke anawaena a me ka mānoanoa i makemake ʻia.

- Lapaʻau Wela: Hoʻokomo ʻia nā paipu i nā kaʻina hana lapaʻau wela e like me ka annealing a i ʻole ka normalizing e hoʻomaikaʻi i ko lākou mau waiwai mechanical.

- Hoʻopau ʻana: Ke hana nei nā paipu i nā kaʻina hana hoʻopau e like me ka hoʻopololei ʻana, ka ʻoki ʻana, a me ka nānā ʻana.

- Hoʻāʻo ʻana: Hana ʻia nā hoʻokolohua like ʻole i nā paipu, me ka hoʻāʻo hydrostatic, ka hoʻāʻo ultrasonic, a me ka hoʻāʻo ʻana o ke au eddy, e hōʻoia i ko lākou maikaʻi.

- Ka Hana ʻIli: Hiki ke uhi ʻia a mālama ʻia paha nā paipu e pale aku i ka pala a hoʻomaikaʻi i ko lākou helehelena.

- Hoʻopili a me ka hoʻouna ʻana: Hoʻopili pono ʻia nā paipu a hoʻouna ʻia i nā mea kūʻai aku.

2. Nā Paipu Kila LSAW (Longitudinal Submerged Arc Welding):

- Hoʻomākaukau ʻana i ka Papa: Ua hoʻomākaukau ʻia nā papa kila kiʻekiʻe no ka hana ʻana i nā paipu LSAW.

- Ke hana ʻana: Ua hana ʻia nā papa i ke ʻano "U" me ka hoʻohana ʻana i ka mīkini kulou mua.

- Kuʻihao: A laila hoʻopili ʻia nā papa ʻano "U" me ka hoʻohana ʻana i ke kaʻina hana kuʻihao arc i lalo.

- Hoʻonui: Hoʻonui ʻia ke humuhumu i hoʻopaʻa ʻia i ke anawaena i makemake ʻia me ka hoʻohana ʻana i kahi mīkini hoʻonui kūloko a i waho paha.

- Nānā: Ke nānā ʻia nei nā paipu no nā hemahema a me ka pololei o ke ana.

- Hoʻāʻo Ultrasonic: Hoʻāʻo ʻia nā paipu i ka ultrasonic e ʻike i nā hemahema kūloko.

- Ke kuʻi ʻana: Ua kuʻi ʻia nā wēlau o ka paipu no ka hoʻoheheʻe ʻana.

- Ka Uhi ʻana a me ka Māka ʻana: Hiki ke uhi ʻia a māka ʻia nā paipu e like me nā koi a ka mea kūʻai aku.

- Hoʻopili a me ka hoʻouna ʻana: Hoʻopili ʻia nā paipu a hoʻouna ʻia i nā mea kūʻai aku.

3. Nā Paipu Kila HFW (Kuʻi Alapine Kiʻekiʻe):

- Hoʻomākaukau ʻana i nā ʻōwili: Ua hoʻomākaukau ʻia nā ʻōwili kila no ka hana ʻana i nā paipu HFW.

- Ke Hana ʻana a me ka Kuʻihao ʻana: Hoʻokumu ʻia nā ʻōwili i loko o ke ʻano cylindrical a laila kuʻihao ʻia me ka hoʻohana ʻana i ka kuʻihao alapine kiʻekiʻe.

- Hoʻomehana ʻana o ke kaula wili: Hoʻomehana ʻia ke kaula wili i ka mahana wili me ka hoʻohana ʻana i ka hoʻomehana induction alapine kiʻekiʻe.

- Ka nui: Hoʻonohonoho ʻia ka nui o ka paipu i hoʻopaʻa ʻia i ke anawaena a me ka mānoanoa e pono ai.

- ʻOki a me ke Beveling: ʻOki ʻia ka paipu i ka lōʻihi i makemake ʻia a beveled ʻia nā wēlau no ka hoʻopili ʻana.

- Nānā: Ke nānā ʻia nei nā paipu no nā hemahema a me ka pololei o ke ana.

- Hoʻāʻo Hydrostatic: Hoʻāʻo ʻia nā paipu no ka ikaika a me nā leaka me ka hoʻohana ʻana i ka hoʻāʻo hydrostatic.

- Ka Uhi ʻana a me ka Māka ʻana: Ua uhi ʻia a māka ʻia nā paipu e like me nā koi a ka mea kūʻai aku.

- Hoʻopili a me ka hoʻouna ʻana: Hoʻopili ʻia nā paipu a hoʻouna ʻia i nā mea kūʻai aku.

Hoʻomaopopo kēia mau kaʻina hana kikoʻī i ke kiʻekiʻe a me ka hilinaʻi o nā paipu kila seamless, LSAW, a me HFW i hana ʻia e Womic Steel, e hoʻokō ana i nā koi koʻikoʻi o nā ʻoihana like ʻole.

Ka Hana ʻIli:

He mea koʻikoʻi ka mālama ʻana i ka ʻili o ke kila pipeline no ka hoʻomaikaʻi ʻana i kona kūpaʻa i ka pala a me ke ola lawelawe. Hoʻohana ʻo Womic Steel i nā ʻano hana mālama ʻili like ʻole e pili ana i nā koi like ʻole mai nā mea kūʻai aku, me:

1. Galvanizing wela-dip: Hoʻokomo ʻia ka paipu kila i loko o ka zinc hoʻoheheʻe ʻia e hana i kahi papa pale zinc-hao, e hoʻoikaika ana i kona kūpaʻa i ka pala. He kūpono ka galvanizing wela-dip no nā paipu maʻamau a me ke kaomi haʻahaʻa.

2. Nā Uhi Anti-corrosion: ʻO nā uhi anti-corrosion maʻamau e komo pū me nā uhi epoxy, nā uhi polyethylene, a me nā uhi polyurethane. Pale pono kēia mau uhi i ka oxidation a me ka corrosion ma ka ʻili o ka paipu kila, e hoʻolōʻihi ana i kona ola lawelawe.

3. Ke one ʻana: Hoʻohana ʻia ka pahū ʻana o ka abrasive wikiwiki e hoʻomaʻemaʻe i ka paipu kila, e wehe ana i ka ʻōpala a me nā mea haumia mai ka ʻili, e hāʻawi ana i kahi kahua maikaʻi no nā hana uhi ma hope.

4. Ka Lapaʻau ʻana i ka Uhi ʻana: Hiki ke uhi ʻia ka ʻili o ka paipu kila me nā pena anti-corrosive, nā pena asphalt, a me nā uhi ʻē aʻe e hoʻoikaika i kona kūpaʻa i ka pala, kūpono no nā paipu lepo a me nā paipu ma nā wahi kai.

Mālama maikaʻi kēia mau ʻano hana mālama ʻili i ke kila pipeline mai ka pala a me ka hōʻino ʻana, e hōʻoiaʻiʻo ana i kona hilinaʻi a me ke kūpaʻa i nā ʻano ʻino like ʻole.

Ka Hoʻopili ʻana a me ka Halihali ʻana:

Hoʻomaopopo ʻo Womic Steel i ka palekana o ka hoʻopili ʻana a me ka halihali hilinaʻi o ke kila pipeline, e hāʻawi ana i nā koho maʻalahi e hoʻokō i nā pono o nā mea kūʻai aku like ʻole:

1. Ukana Nui: No nā kauoha nui, hiki ke hoʻouna ʻia ke kila paipu ma ka nui me ka hoʻohana ʻana i nā mea lawe nui kūikawā. Hoʻouka pololei ʻia ke kila i loko o ka moku me ka ʻole o ka ʻōpala, kūpono no ka lawe ʻana i nā nui he nui me ke kumukūʻai kūpono.

2. LCL (ʻOi aku ka liʻiliʻi ma mua o ka ukana ipu): No nā kauoha liʻiliʻi, hiki ke hoʻouna ʻia ke kila pipeline ma ke ʻano he ukana LCL, kahi e hoʻohui ʻia ai nā kauoha liʻiliʻi he nui i loko o hoʻokahi ipu. He kūpono kēia ʻano hana no nā nui liʻiliʻi a hāʻawi i nā papa hana hoʻouna maʻalahi.

3. FCL (Full Container Load): Hiki i nā mea kūʻai ke koho no ka hoʻouna ʻana ma FCL, kahi i hoʻolaʻa ʻia ai kahi pahu piha no kā lākou kauoha. Hāʻawi kēia ʻano hana i nā manawa lawe wikiwiki a hoʻemi i ka pilikia o ka hōʻino ʻia i ka wā e lawelawe ai.

4. Ukana Ea: No nā kauoha wikiwiki, loaʻa ka ukana ea no ka lawe wikiwiki ʻana. ʻOiai ʻoi aku ke kumukūʻai ma mua o ka ukana kai, hāʻawi ka ukana ea i ka halihali wikiwiki a hilinaʻi hoʻi no nā ukana manawa koʻikoʻi.

Hoʻomaopopo ʻo Womic Steel ua hoʻopili pono ʻia nā ukana āpau e pale aku i ka pōʻino i ka wā o ka lawe ʻana. Hoʻopili pinepine ʻia ke kila i nā mea pale a hoʻopaʻa ʻia i loko o nā ipu a i ʻole ma nā pallets e hōʻoia i ke kūpaʻa i ka wā o ka lawe ʻana. Eia kekahi, hana pū ka ʻoihana me nā hoa hoʻouna kaulana e hōʻoia i ka lawe ʻana i ka manawa kūpono a me ka hoʻokele logistics kūpono.

Nā hiʻohiʻona noi:

Hoʻohana nui ʻia nā paipu laina API 5L i hana ʻia e Womic Steel i nā ʻoihana ʻaila a me ke kinoea kūlohelohe no ka lawe ʻana i ka ʻaila, ke kinoea, a me nā wai ʻē aʻe. Hoʻohana ʻia nō hoʻi lākou i nā ʻoihana like ʻole e like me ka hana kemika, ka hana mana, a me ke kūkulu ʻana.

Hopena:

He mea hana hilinaʻi ʻo Womic Steel no nā paipu laina API 5L, e hāʻawi ana i nā huahana kiʻekiʻe e hoʻokō ana i nā koi koʻikoʻi o nā ʻoihana ʻaila a me ke kinoea kūlohelohe. Me ka nānā ʻana i ka maikaʻi, ka hilinaʻi, a me ka ʻoluʻolu o ka mea kūʻai aku, ke hoʻomau nei ʻo Womic Steel i koho makemake ʻia no nā mea kūʻai aku ma ka honua holoʻokoʻa.

Ka manawa hoʻouna: Malaki-22-2024